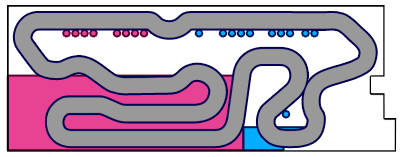

Whenever special bottles (rectangular, square, oval, etc.) are handled, it is not possible to put them on an accumulation table, consequently a worm infeed system is required.

The bottles are spaced by an infeed scroll and fed to the inload slides through a pushing device which is lined with polyethylene.

Moreover a bar will introduce the bottles into the baskets.